Tech Companies Face Supply Chain Risk as Typhoon Soudelor Strikes Taiwan, Soon China

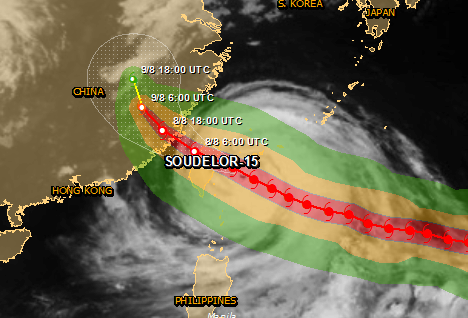

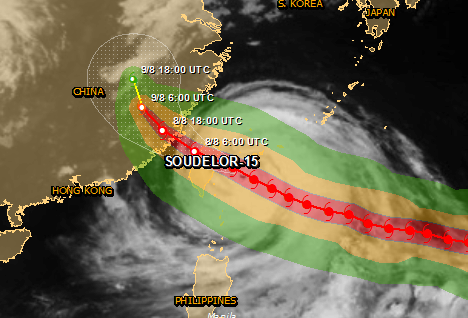

Typhoon Soudelor hit Taiwan on Saturday at 5 a.m. local time, according to The Weather Channel LLC..

Typhoon Soudelor hit Taiwan on Saturday at 5 a.m. local time, according to The Weather Channel LLC..

Resilinc has published its 2015 supply chain events annual report which summarizes and analyzes…

The supply chain event impact, while still being assessed, clearly can be characterized as minor…

Get ahead of hurricane season 2024 by knowing about climate change supply chain disruptions before they happen.