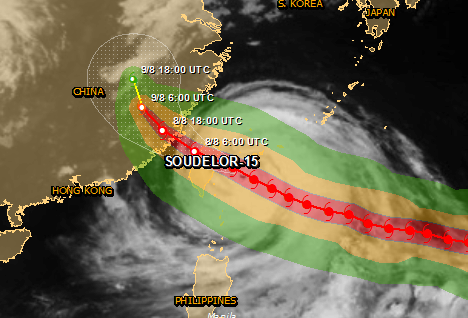

Typhoon Soudelor hit Taiwan on Saturday at 5 a.m. local time, according to The Weather Channel LLC.1 The storm moved across Taiwan, before moving on to mainland China.2

More than 35,000 military officials were deployed to help relocate those in vulnerable areas to Typhoon Soudelor.3 Thousand have also been evacuated from their homes. Numerous businesses, especially those in the tech industry, utilized risk prevention measures to ensure their supply chains faced as little impact as possible. At this time, the damage is still being assessed but four million Taipower customers suffered power outages, a record number of outages previously held by Typhoon Herb, which left 2.79 million powerless in 1996.4

Typhoon Soudelor’s heavy rains of more than 50 inches and major winds caused the highest potential for flooding, mudslides, and other damage, already causing a landslide in at least one area of Taiwan, according to BBC.

Home to hundreds of businesses and heralded for its booming tech industry, Taiwan ranks as one of the biggest producers of PC, LCD, semiconductor, and chip technology. In fact, three of the largest semiconductor suppliers in the world are based in Taiwan, with the Taiwan Semiconductor Manufacturing Co. Ltd. (TSMC) ranking in the No. 3 spots in 2015, according to a report from IC Insights.5

Numerous other tech companies in the Information and Communications Technology (ICT) space also reside in Taiwan. With ICT such a large revenue generator of Taiwan,6 supply chain risk is perhaps most relevant for suppliers and manufacturers in this space as a result of Typhoon Soudelor.

To proactively prepare against disruptions to a company’s supply chain, such as factory fires, floods, other natural disasters, or labor issues, businesses can analyze supply chain risks before they occur through global supply chain event monitoring.

By utilizing solutions that monitor events posing potential supply chain risks before they happen, tech companies, for example, may not only better ward off scenarios such as that created by Typhoon Soudelor’s ongoing damage, but also ensure an effective, real-time response plan.

Risks affecting tech companies may include:

- Multi-tier supply chain service disruptions—Not only do tech companies’ direct suppliers based in Taiwan face risks if impacted by Typhoon Soudelor, but so do any of their supply chain’s sub-tier suppliers, sub-contractors, and manufacturers located in the region. Without proper supply chain visibility and supply chain mapping, determining which companies’ sites and parts will be impacted could require wasted hours or days of research. To address risks before they occur, tech companies should consider utilizing virtual war room functionality to ensure complete supply chain visibility and better analyze each supplier’s potential disruptions based on location.

- Potential for major supply chain bottlenecks—In the case of a disruptive event such as what we are beginning to see in the aftermath of Typhoon Soudelor, according to Bindiya Vakil, CEO of Resilinc, “Disruptive events can often create major supply chain bottlenecks which can cause widespread profit leakages for customers as inventory dries up and capacity shortages result in higher raw material prices. In these high disruption allocation situations [such as what we might see with Typhoon Soudelor], no one in the supply chain can get an adequate supply of the necessary raw materials or parts.” Especially in the high tech industry and with Taiwan’s high concentration of semiconductor fabs, competing with other companies for scarce resources is a likely outcome. Using a 24/7 global event monitoring service could be the edge a company needs to react quickly and decisively, leveraging real-time event detection and impact analysis. When hooked up to virtual war room functionality, this supports the rapid mobilization of focused and coordinated crisis response and recovery strategies and playbooks.

- Reputational risk—How a business mitigates risk and accounts for the actions taken by all parties within their multi-tier supply chain is critical to their brand and corporate profile. Hurricanes and typhoons are a large element of understanding that risk and how to account for it, as such natural disasters continue to rank in the top three types of supply chain disruptions. A sign that more businesses continue to understand the relevance of this is through the growth of Corporate Social Responsibility (CSR) reporting. A few of the measures businesses can take to ensure complete accountability of their supply chain can include using the right tools to address suppliers located in high-risk areas or collect information about suppliers to ensure they provide the necessary service a business needs.

Proactively planning for risks can help companies better position themselves as leaders in ensuring complete supply chain visibility. The right solutions can help companies with multi-tier supply chains understand how supply chain risks impact not only their sites but product and revenue levels as well.

Resilinc EventWatch is actively monitoring the situation and providing live updates to EventWatch subscribers, as more reports come in about the impact on Taiwan and make landfall in China. Click below to learn more about the premier supply chain event monitoring service.

{{cta(‘f231fd2f-e6fa-4221-8512-4bb9ada36404’)}}

Resources

-

The Weather Channel LLC. Typhoon Soudelor Makes Landfall in Taiwan; 145-MPH Gust In Japan’s Ryukyu Islands; More Than 4 Feet of Rain in Taiwan”

-

BBC. “Deadly Typhoon Soudelor Batters Taiwan”

-

CNN. “Powerful Typhoon Soudelor Slams Into Taiwan “Typhoon Soudelor Impacts: At Least 6 Killed In Taiwan; Evacuations Ordered in China; Record-Breaking Power Outages Recorded”

- The Weather Channel LLC. “Typhoon Soudelor Recap: 145-MPH Gust In Japan’s Ryukyu Islands; More Than 50 Inches of Rain in Taiwan”

-

IC Insights. “Six Top 20 1Q15 Semiconductor Suppliers Show >20% Growth”