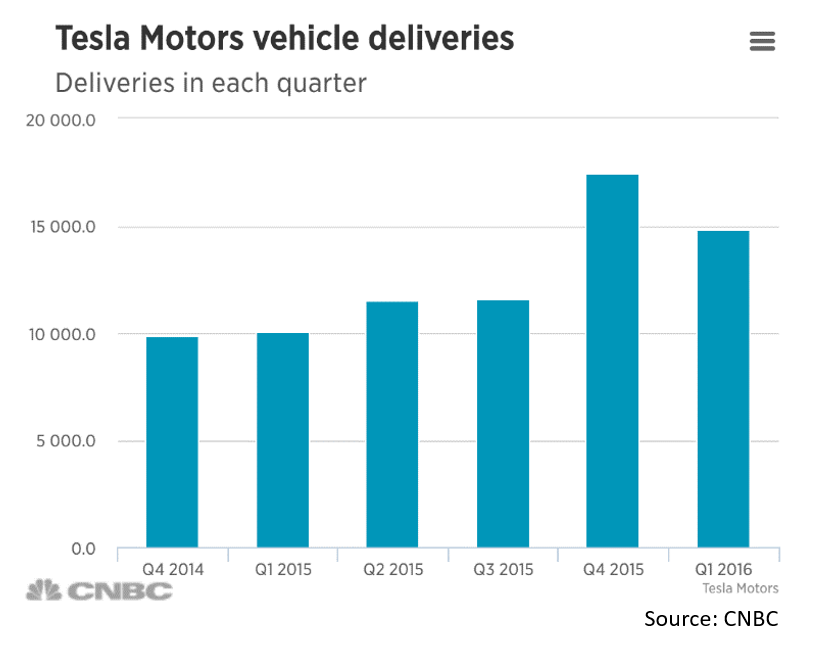

Tesla announced in early April that it was unable to meet its delivery target of 16,000 vehicles for the quarter due to component shortages on about half a dozen of its 8000 parts. At prices for Tesla cars starting at $70,000, the delivery shortfall equates to almost a $100 million gap, which is not minor by any means. In the aftermath of the announcements, Tesla announced the departure of two senior manufacturing and production executives, Greg Reichow, it’s vice president of production, and vice president of manufacturing, Josh Ensign.

Tesla’s experience is unfortunately a problem that many CEOs grapple with, as it relates to the supply chain. Because the supply chain is still managed in very traditional ways, there is always a risk that it will let you down when it counts most.

Typically, supply chain flexibility, component shortages, issues with key direct suppliers are worries that keep CEOs up at night when their supply chain and sourcing organizations fail them. And unfortunately, this happens more often than it should considering the complex symphony of parts and processes that go into building a high-tech product – a single component or contentious supplier can stymie the entire production and delivery of a new model.

The supply chain should not be a hindrance to achieving the CEOs’ growth ambitions or revenue targets. For smart companies, the supply chain can be a game-changer, and a tool to be wielded for gaining competitive advantage.

The supply chain should not be a hindrance to achieving the CEOs’ growth ambitions or revenue targets. For smart companies, the supply chain can be a game-changer, and a tool to be wielded for gaining competitive advantage.

Take the example of Apple for a moment. With Tim Cook’s extensive expertise in supply chain and operations, he provided Apple that game-changing opportunity in 2011 using multi-tier supply chain intelligence. When launching the iPad, Apple announced it had invested almost $4 billion dollars in a capacity option for touchscreen capacity and effectively locked out the competition for several years. Apple dominated the tablet market for almost 3 years before competitors entered the fray. The $4 billion capacity option resulted in over $110 billion in iPad revenues.

Tesla Motors is heralded as a “different type of car company.” Therefore, one would expect that Tesla would adopt the best in class supply chain management intelligence and analytics capabilities, such as multi-tier visibility, vulnerability analytics, comprehensive supplier risk assessments, and proactive supplier capacity risk management. These techniques would put them ahead of potential problems and give Tesla the ability to identify them and manage/mitigate them before they manifest or escalate. Younger companies can be disruptive on more than just their technology or design vision. They are not encumbered by old mindsets, archaic tools, or extensive change management challenges.

In the next blog of our upcoming CEO series, we will talk about how a young, fast-growing Silicon Valley company called Palo Alto Networks is best in class when it comes to harnessing the power of information and analytics to gain arbitrage opportunities that provide its supply chain a huge competitive advantage.

- Pramuk, Jacob. “Tesla Pops 4% on Results, Production Outlook.” CNBC. N.p., 04 May 2016. Web. 26 May 2016.

- Ard, Scott. “Tesla Blames “Hubris” for Falling Short on Actual Deliveries in the First Quarter.” BizJournal. N.p., 4 Apr. 2016. Web. 26 May 2016.

- Field, Kyle. “Multiple Causes Linked To Tesla Model X Delays.” CleanTechnica. N.p., 21 Jan. 2016. Web. 26 May 2016.

- “Tesla (TSLA) Delivered 14,820 Vehicles in Q1 vs. 16,000 Expected.” Street Insider. N.p., 4 Apr. 2016. Web. 23 May 2016.