Part 1: Starting the SCRM Journey

Wherever your organization is on the journey to a mature and robust SCRM program, this four-part blog series—based on the Ultimate Guide to Supply Chain Resiliency Program Success co-authored by Resilinc and the Global Supply Chain Resiliency Council—should be helpful. At a minimum, it can provide validation and a checklist to ensure that every element of your SCRM has been optimally developed and that you’re not leaving significant opportunities to increase ROI on the table.

The series begins with this introduction and will be followed by articles summarizing the three major phases of creating a mature, resilient SCRM program: Plan, Implement and Institutionalize.

Like most readers of Resilinc’s blog, you probably agree that improving supply chain resiliency should be a core strategic goal for your company—and for any large manufacturing company. You may even be part of an organization whose leaders endorse this viewpoint and whose supply chain risk management (SCRM) program is relatively mature and already delivering return on investment.

Or you may be in the early stages of seeking buy-in from C-level leaders for a supply chain resiliency effort. Alternatively, you may be facing a situation in which the SCRM program you thought was truly robust was revealed as lacking by the turmoil of COVID-19.

Even before the pandemic, there had been many instances in which corporations with mature supply chain capabilities lost their edge and experienced harsh consequences in the form of costly disruptions.

A three- to five-year journey

Developing a supply chain risk management program that optimizes ROI is a long and complex journey—one that typically requires three to five years. And even after a company’s SCRM program has reached a high level of maturity, managers must constantly work to refine it and communicate its benefits internally to retain C-level support and the participation of category managers and functional teams.

But the benefits in terms of ROI can be game-changing. In Resilinc’s experience—which incorporates hundreds of years of collective staff experience and close collaboration with our customers in many industries—a truly mature SCRM program can yield as much as $15 million in ROI annually for every $1 billion in sales.

A robust and mature enough process to yield these kinds of results must have all of these characteristics:

1) Real-time event monitoring and alerts in place;

3) Reasonable sub-tier visibility achieved on constrained materials or historically weak suppliers;

4) Proactive risk mitigation enabled for critical high-impact, high-vulnerability suppliers, including all their sites and all the parts they make for you;

5) Your supply chain risk mitigation strategies optimized based on potential revenue impacts—and not on how much you spend with a supplier;

6) Cross-functional core teams collaborate monthly to set goals and execute mitigations; and

7) Risk insights inform product design decisions.

This may sound daunting, but supply chain professionals have an unusual ally this year in their quest for greater resiliency: the COVID-19 pandemic, which revealed the weaknesses in supply chains that had been designed to optimize cost savings above resiliency.

But while COVID-19 forced senior managers to pay more attention to supply chain resiliency, it will still require careful analyses and skillful presentations to convince C-level leaders to invest significant dollars in a SCRM program. As further detailed in the upcoming Plan post, whether you’re proposing a new program or seeking support to upgrade an existing one, the first step is building the business case.

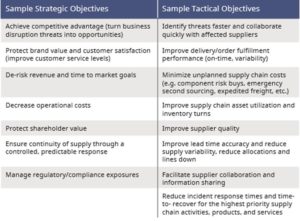

Some key principles to remember as you start this process: your proposal for an SCRM program must show how its purpose and goals are aligned with the company’s strategic goals, especially to targets for growth, revenues, gross margins and EBIDTA. It’s also important to tie strategic goals to the tactical objective of SCRM. As the chart below demonstrates, this will allow senior managers, category managers and functional leads to visualize with greater clarity just how risk management advances company strategy.

POTENTIAL STRATEGIC AND TACTICAL OBJECTIVES

Next week’s post will start with guidance on developing this critical metric in a credible and defensible manner.