The conversations around Big Data are endless—and for good reason. Essentially, Big Data provides a company with more information on all levels including its clients, industry trends, audience engagement patterns, business challenges, buyer personas, and much more. Add to that its benefits—such as improved supply chain management (SCM), increased multi-tier visibility, greater business efficiency, and relationship management—and one could question how a company can ever go without Big Data.

In fact, a vast majority of business executives (97 percent) understand how Big Data can benefit their supply chains.1 While its usage is also already evident in numerous industries, some companies remain challenged with Big Data investment cost, security and privacy issues, and data needs that require careful consideration of Big Data’s application before complete implementation.

To better help you understand how Big Data can fit your plan for business growth, here we outline five reasons why you can no longer overlook Big Data for supply chain discussion.

1. Big Data growth shows no signs of slowing down.

Generally defined as “data of a very large size, typically to the extent that its manipulation and management present significant logistical challenges,2” the topic of Big Data can be traced back to early reports3 that foresaw the growth of new information and its impact on technology. According to a report from IDC, the Big Data technology and services market will grow at a 26.4 percent compound annual growth rate (CAGR) to $41.5 billion through 2018.4 The growth provides opportunities for businesses to begin or continue discussions around the topic as it relates to their supply chain. In fact, more than one-third of executives engage in serious conversations to implement analytics in the supply chain, and 3 out of 10 already have an initiative in place to implement analytics.5

2. More industries, including healthcare, automotive, and high-tech, recognize the need for Big Data.

For example, 95 percent of healthcare CEOs said they were exploring better ways to harness and manage big data, according to PwC’s Annual Global CEO survey.6 While only 25 percent of healthcare companies made innovative changes and 36 percent have made some progress in regards to Big Data, a large majority of healthcare CEOs agree that technology will change the way healthcare service is delivered.

Other industries that witnessed their share of data impacts include both the automotive and high-tech space. Thanks to plug-in hybrid vehicles—some of which generate 25TB of data in one hour7— MapQuest, Google Maps, and global positioning system (GPS) providers such as TomTom and Garmin, the automotive space is better positioned to further adopt Big Data than perhaps companies with no record of data analysis or measurement. In addition, Big Data’s evolution, in relation to self-driving cars, responsible sourcing, or automotive parts manufacturing, can play a big impact on automotive supply chain processes.

In the high tech space, providers of service, software, and hardware continue to monetize on data insights to set themselves apart from their competition. In addition, the use of data can more often than not enable companies to better collect information about minerals they should not be used in high-tech products. For example, a single, centralized data repository and a single, consistent, and repeatable data collection process can enable companies to better report on conflict minerals. Reporting on where minerals used in company products came from is already a requirement under the 2010 Dodd-Frank Wall Street Reform and Consumer Protection Act to prevent the use of conflict minerals (i.e. those minerals that originated in the Democratic Republic of the Congo or an adjoining country, according to the Securities and Exchange Commission). By already having that data, companies can prevent high-tech supply chain risk (such as those associated with conflict minerals) by accessing data that allows them to see the product, product category, part, and raw material-level data.

3. Companies that want more supply chain collaboration should be open to an ‘unstructured’ approach.

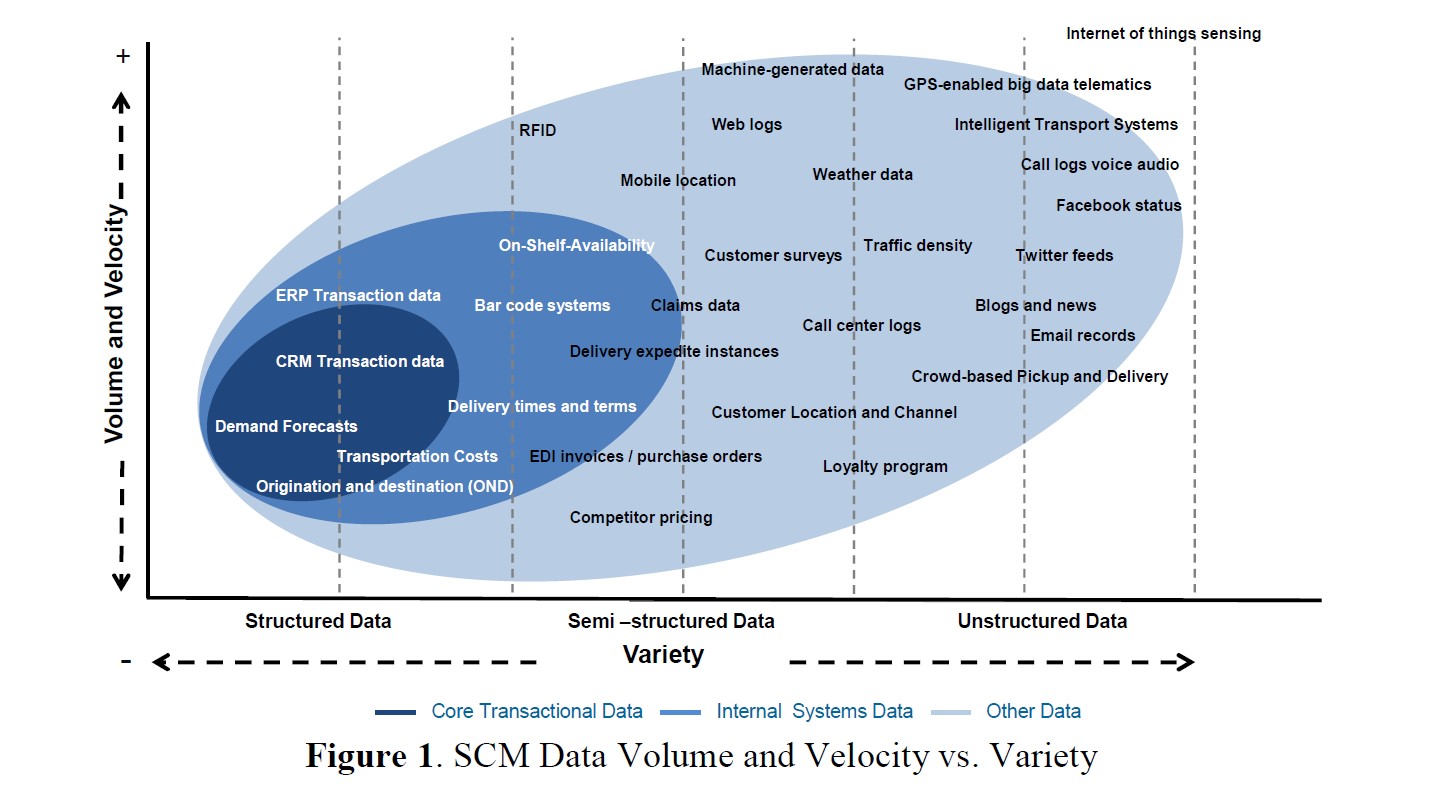

Keep in mind, the graphic may not account for data analysis used with extended ERP systems or ones that work in tandem with Business Intelligence (BI) solutions. Numerous businesses still use a multi-faceted ERP and BI approach to track such key performance indicators (KPIs) as managed spend, receivables, order-to-ship cycle times, invoices, and manufacturing cycle times.9 In order to transition to Big Data analysis, businesses must account for what data their current systems measure and store, the data capacity of their existent SCM systems, their overall strategy when it comes to Big Data, and at which point should they transition to more scalable technologies. For example, companies that used an enterprise-wide strategy (versus a process-focused strategy) witnessed greater supply chain benefits, according to Accenture. Such benefits included a 10 percent-plus increase in supply chain efficiency, a faster and more effective reaction time to supply chain issues, and greater supply chain integration.10

4. Is more legislation around Big Data necessary?

The question is one that continues to receive increasing attention. The reality of data breaches, cyber-security threats, enterprise risk, and compliance issues in managing IT environments all call for greater accountability in protecting corporate and consumer data. In response, President Barack Obama called for a 90-day review in 2014 of Big Data and privacy. A progress report, released in 2015, shows that numerous actions were taken, including the revised Personal Data Notification & Protection Act and the Student Digital Privacy Act, announced in January 2015, to enhance student privacy.11

The Federal Trade Commission (FTC) also continues to examine the impacts of Big Data on consumers and industries alike, in numerous educational workshops and reports, confirming that certain laws need to be followed. For example, in 2013, the FTC filed charges against Time Warner Cable Inc. for violating the 2011 Risk-based Pricing Rule.12 According to the FTC, the Rule requires, “creditors to provide consumers with a ‘risk-based pricing’ notice when, based on the consumer’s credit report, the creditor provides credit to the consumer on less-favorable terms than it provides to other consumers.13”

5. Need for increased Information Technology (IT) and data analysis skills.

With Big, Data growth comes the demand for computer generalist or “data scientists.” According to research from Gartner, 4.4 million IT jobs will be created by 2015, however, only one-third of the jobs will be filled.14 As such, businesses may want to consider addressing the rapidly evolving use of Big Data analysis and talent shortage. They may choose to train their current employees with the data analytics skills necessary to effectively manage and analyze Big Data. If possible, they may also consider: 1). onboarding talent with advanced computer programming, IT, or data analysis skills; or 2). using data collection software that also provides built-in analytics and reporting for easy data configuration, to address the role of Big Data in their supply chains.

There are many ways businesses implement SCM processes to ensure the effectiveness of their supply chains—and Big Data continues to be a growing part of that process.

Want to know if you’re at the point of needing to change your SCM processes to manage Big Data? Learn how Resilinc Data Services can ensure accurate data validation with the right solutions for complete end-to-end supply chain consistency.

References

- Big Data Analytics in Supply Chain: Hype or Here to Stay? Accenture, 2014: https://www.accenture.com/t20150523T024812__w__/in-en/_acnmedia/Accenture/Conversion-Assets/DotCom/Documents/Global/PDF/Dualpub_2/Accenture-Global-Operations-Megatrends-Study-Big-Data-Analytics.pdf

- Oxford English Dictionary: http://www.oed.com/view/Entry/18833?redirectedFrom=big+data#eid301162177

- The University of California, Berkeley, October 2003: http://www2.sims.berkeley.edu/research/projects/how-much-info-2003/execsum.htm

- International Data Corporation (IDC):https://www.idc.com/prodserv/4Pillars/bigdata

- Big Data Analytics in Supply Chain: Hype or Here to Stay? Accenture, 2014: https://www.accenture.com/t20150523T024812__w__/in-en/_acnmedia/Accenture/Conversion-Assets/DotCom/Documents/Global/PDF/Dualpub_2/Accenture-Global-Operations-Megatrends-Study-Big-Data-Analytics.pdf

- IBM Big Data for the Automotive Industry, IBM Corp., August 2013: http://www.oesa.org/Doc-Vault/Knowledge-Center/Operational-Performance-Content/IBM-Big-Data-for-Auto-Industry.pdf

- Big Data Analytics in Supply Chain Management: Trends and Related Research, ResearchGate, 2014: http://www.researchgate.net/publication/270506965_Big_Data_Analytics_in_Supply_Chain_Management_Trends_and_Related_Research

- Using ERP and BI to Turn Data into Insights, SMB Group, November 2011: http://www.smb-gr.com/wp-content/uploads/2012/pdfs/SAP_Business_All_in_One_paper2.pdf

- Big Data Analytics in Supply Chain: Hype or Here to Stay? Accenture, 2014: https://www.accenture.com/t20150523T024812__w__/in-en/_acnmedia/Accenture/Conversion-Assets/DotCom/Documents/Global/PDF/Dualpub_2/Accenture-Global-Operations-Megatrends-Study-Big-Data-Analytics.pdf

- Time Warner Cable to Pay $1.9 Million Penalty for Violating the Risk-Based Pricing Rule, Federal Trade Commission (FTC), December 2013: https://www.ftc.gov/news-events/press-releases/2013/12/time-warner-cable-pay-19-million-penalty-violating-risk-based

- FTC, Federal Reserve Board Issue Final Changes to Risk-Based Pricing Rule, Federal Trade Commission (FTC), July 2011: https://www.ftc.gov/news-events/press-releases/2011/07/ftc-federal-reserve-board-issue-final-changes-risk-based-pricing

- Gartner Says Big Data Creates Big Jobs: 4.4 Million IT Jobs Globally to Support Big Data By 2015, Gartner Inc., October 2012: http://www.gartner.com/newsroom/id/2207915

Additional Resources

- The Securities and Exchange Commission: http://www.sec.gov/rules/final/2012/34-67716.pdf