Learn how implementing an Enterprise Risk Management framework can help your company on the journey to operational resilience.

Businesses have started to see risk management as a necessary facet of running a successful company. In a 2023 survey conducted by EY, 90% of respondents said their organization has directly invested in third-party risk management. In 2022, the U.S. market size for risk management was valued at $0.44 billion but was expected to grow to $1.07 billion by 2032. Incorporating Enterprise Risk Management (ERM) into your overall business strategy is now more important than ever in 2024.

In this blog, we break down the basics of enterprise risk management. Then, we lay a framework for enhancing your ERM program with actionable steps your company can take. We explore the benefits of ERM (like real ROI and competitive advantage), as well as the tools you can use to unlock those benefits. Let’s first understand the meaning of “enterprise risk management” and how it relates to supply chain risk management.

What is Enterprise Risk Management?

According to Stanford University, Enterprise Risk Management (ERM) can be defined as, “a business continuous process, led by senior leadership that extends the concepts of risk management.” This process includes identifying risks, assessing the impact of risks, developing mitigation plans, and monitoring risks. Enterprise Risk Management is important because risks are ever-present and require the strong governance of an executive leadership team to make significant, strategic changes that build a culture of resilience.

How is ERM different from traditional risk management?

Both have similar goals—seeking to identify, assess, and mitigate risk—but they each approach the problem differently. Traditional risk management is often delegated to a department or team focused on mitigating specific risks. ERM, on the other hand, has a much larger scope. It is incorporated into a business’s overall strategy, allowing for a more proactive approach to managing risk.

How is ERM different from supply chain risk management?

ERM and supply chain risk management (SCRM) go hand in hand. On the surface, SCRM focuses on mitigating risks specifically related to procurement, while ERM is a larger framework that focuses on managing risks across the entire organization. However, supply chain risk management overlaps with ERM since supply chain risks often run much deeper than procurement. For example, a company could have trouble importing raw materials from China due to export controls. While this is a supply chain issue, it also can lead to enterprise-level conversations about strategies like nearshoring, reshoring, or China Plus One.

Tools for Creating an Enterprise Risk Management Framework

A successful ERM and SCRM identifies risks, assesses the impact of risks, develops mitigation plans, and monitors risks. How can businesses successfully incorporate each component of ERM? Let’s break it down into an actionable framework with tools that can help you achieve each step.

Multi-Tier Mapping for Identifying Risk and Gaining Visibility

Do you know where risks exist in your supply chain? 85% of supply chain disruptions occur in the sub-tiers of the supply chain—where sub-contractors, component suppliers, and mines operate. If your company doesn’t have visibility into those tiers, you will be unable to see the potential risks. For example, imagine a crucial five-cent part comes from one factory near the Red Sea—but your company doesn’t know this. When the Red Sea ship attacks occurred, your company would be unaware of this sole source and would not have time to mitigate the risk.

Mapping your supply chain is the key to unlocking the visibility necessary to start identifying risks. Learn how Resilinc helps companies identify hidden supply chain weaknesses: Multi-Tier Mapping.

EventWatchAI for Monitoring, Assessing Impact, and Mitigation

Resilinc’s EventWatchAI supply chain monitoring platform enables companies to manage many aspects of risk management all from one dashboard—taking companies from notification to mitigation in minutes. EventWatchAI starts by scanning over 104 million sources and sites 24/7 in over 100 languages to uncover potential disruptions that could affect your company.

From there, it sends tailored alerts to your inbox to help you assess the impact of a disruption. For example, each alert includes a disruption potential rating (from low to severe), a synopsis of the disruption, including which industries were impacted and what next steps your company should take to mitigate potential risks. If your company is likely to be impacted, EventWatchAI creates a WarRoom where you can collaborate directly with suppliers to confirm the impact and mitigate the risk. Learn more about Resilinc’s supply chain monitoring platform EventWatchAI.

Using a Risk Maturity Model (RMM) to Evaluate Progress

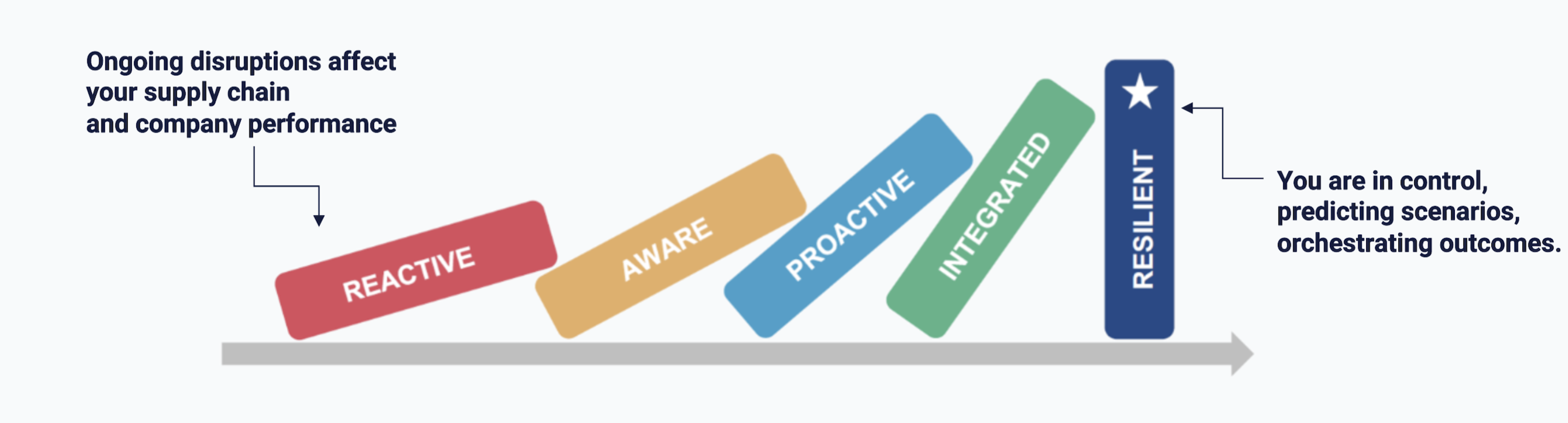

Finally, a risk maturity model (RMM) is an assessment tool your company can use to gauge progress toward ERM goals. At the beginning of the risk maturity model, companies are purely reactive to incoming risks. Ongoing disruptions constantly affect the supply chain and company performance since the company must constantly keep up with the latest disruptions. As an organization moves through the RMM, it will slowly shift from being reactive to being proactive and planning for potential disruptions until eventually becoming resilient. In this stage, the company is in control, predicting scenarios, orchestrating outcomes, and enjoying the other benefits of resiliency (also known as operational resilience).

Benefits of Implementing an Enterprise Risk Management Framework

Having a robust ERM program in place is becoming more and more important. Resilinc’s CEO, Bindiya Vakil, predicts that The Top 5 Supply Chain Megatrends of 2024 will be geopolitics, climate change, cyber attacks, ESG, and labor issues. These are trends that will impact all levels of an organization, not just the supply chain. And the frequency, magnitude, and associated costs of supply chain disruptions are increasing by the day.

Proactively working as an organization to mitigate these risks can have astounding rewards, including enhanced operations, competitive advantage, added value, and true ROI. Ready to implement your own ERM or SCRM program today? Learn more about the benefits of getting started. Check out our whitepaper The ROI of Supply Chain Resilience: It’s More Than You Think